Guangzhou Yushun XinCai Co., Ltd. was established in October 2015. The company's main business is all kinds of ultrafine quartz powder, micro silicon powder, talcum powder and other related products and surface treatment products. The company has a series of automatic production equipment and testing instruments such as powder ultra-fine grinding, precision grading, surface coating to compound mixing. Company has been committed to the high purification, ultra-fine, spheroidization and Its surface coating treatment and other deep processing since its establishment. As one of the top three domestic enterprises in terms of silicon powder output, company’s first production line was put into operation at the end of 2015. In 2021, the company's production capacity of various silicon powders will reach 50,000 tons. While gradually expanding production capacity, Yushun quickly entered the supply system of leading downstream customers. The main customers include Kingboard Holdings Limited, ITEQ corporation, Grace electron , WAZAM New Materials, NouYa New Materials, Nbetg Electronics, Huitian New Materials, Qing Tianxin Materials, etc., covering multiple downstream markets such as copper clad laminate industry, electronic adhesive industry, and coating industry. Yushun continues to invest in the research and development of new products and new processes; it has more than 20 related technology research and development patents. Company’s existing products are fused silica powder, crystalline silica powder and composite soft filler. In the future, spherical silica powder and spherical alumina will be applied into the product line. Yushun plans to complete the Pre-A round of financing in the near future, expand production capacity and establish 20,000 tons of spherical silicon production base, to seize the domestic spherical silicon powder market.

Industry View:

Spherical micro silica powder market - large demand potential; reliance on imports

According to the "2020-2025 In-Depth Market Research and Investment Prospect Analysis Report on Spherical Microsilica Powder Industry" released by Newsijie Industry Research Center, due to the rapid development of the terminal industry, the global market demand for spherical micro-silica powder continues to rise. In 2019 The market size reached about 150,000 tons, and the market size has maintained a continuous growth rate of about 8% in the past five years. It is expected to reach 238,000 tons in 2025. According to the "2022-2027 In-depth Market Research and Development Prospect Forecast Report of China's Silicon Micro-powder Industry" released by Newsijie Industry Research Center, the market size of China” silicon micro-powder industry will reach 2.46 billion CNY in 2021, a year-on-year increase of 17.9%. Breakthrough 5.50 billion CNY.

Taking the copper clad laminate industry as an example, the silicon micro-powder currently used in copper clad laminates includes spherical silicon micro-powder, crystalline silicon micro-powder, and fused silicon micro-powder. Among them, spherical silicon micro-powder has a higher application prospect due to its better fluidity and higher filling rate. However, due to the complex production process and high product price of spherical silicon micro-powder, the current application ratio in the field of copper-clad laminates is relatively low. With the commercialization of 5G, the electronic information industry is gradually developing towards high-end, and the quality requirements of copper-clad laminates for silicon micro-powder are increasing. Spherical silicon micro-powder is expected to have a high demand in the field of copper-clad laminates. It has already accounted for about 72% of the total global market, and the production capacity continues to be transferred to China”s. Therefore, there is a huge application space for spherical silica powder in the Chinese market in the future. It is estimated that by 2025, the proportion of spherical silicon micro-powder in copper clad laminates will reach more than 60%.

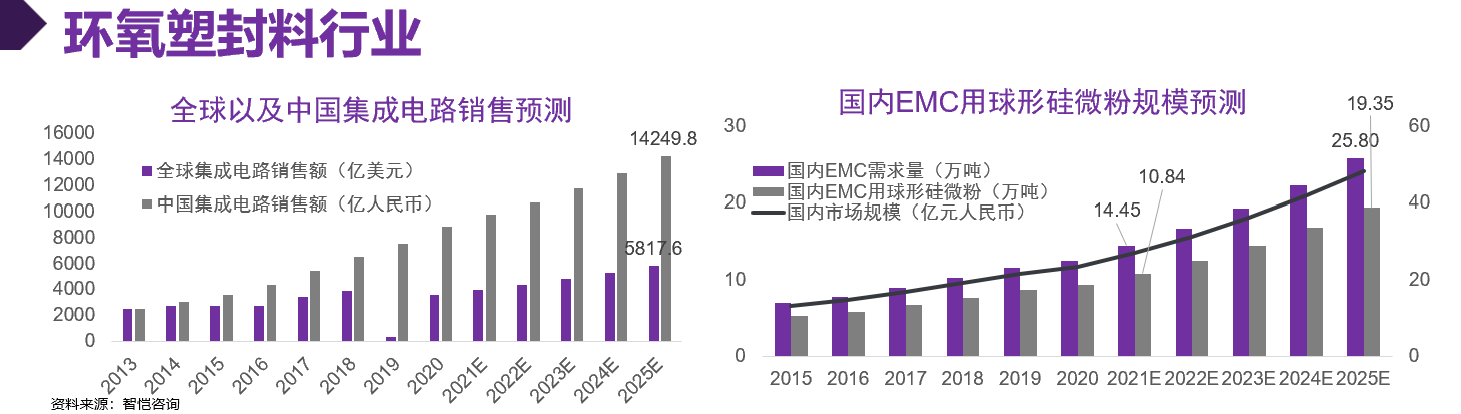

When talking the epoxy molding compound industry, the epoxy molding compound is made of epoxy resin as the matrix resin, high-performance phenolic resin as the curing agent, silicon micro-powder as the filler, and various additives. , is the key material used to package chips in electronic products. Ultra-large-scale and ultra-large-scale integrated circuits represented by high-end chips have higher and higher requirements for packaging materials, not only requiring ultra-fine fillers in packaging materials, but also requiring them to have high purity and low content of radioactive elements. A spheroidization requirement is put forward for the particle morphology. Spherical micro silica powder has excellent properties such as high heat resistance, high humidity resistance, high filling rate, low expansion, low stress, low impurity, and low friction coefficient, and has become an indispensable functional filling material in ultra-large-scale and ultra-large-scale integrated circuit packaging materials. . At present, 97% of global integrated circuit (IC) packaging materials use epoxy molding compound (EMC), and silicon micro-powder filler accounts for 80-95% of epoxy molding compounds by weight.

According to the report "A Brief Analysis of the Development of Silicon Micro-powder Industry" released by the China Non-Metallic Mineral Industry Association in July 2017, "the spherical silica powder used in domestic epoxy plastic sealing materials mainly relies on imports. According to China country's semiconductor integrated circuits and devices According to development plan, in the next 4-5 years, China”' demand for spherical silica powder will reach more than 100,000 tons. At present, the domestic consumption of spherical silica powder used only for VLSI plastic packaging materials has exceeded 3,000 tons." According to ZK Consulting In summary, in 2020, the domestic demand for micro-silica powder for EMC will reach 90,000 tons, and the market size will exceed RMB 2.3 billion. In 2025, the domestic demand for spherical silicon micro-powder used only for VLSI plastic packaging materials will reach 190,000 tons, and the market size will reach 4.8 billion CNY, with a compound annual growth rate of about 15.59%.

In terms of production, 75% of the global spherical silica powder market is occupied by Japanese companies. Representative companies include Toshiba Fusion, Shin-Etsu, Admatechs, etc., among which Admatechs has almost monopolized the spherical silica powder market below 1um. Although China spherical silica powder production technology has made breakthroughs in recent years, there is still a gap with foreign products in terms of product purity and particle size. The domestic market demand still relies on imports, and domestic spherical silica powder accounts for about 15%.

Ending

In the next five years, with the promotion of 5G, semiconductors and other industries, the rapid development of copper-clad laminates and epoxy molding compounds will continue to drive the demand for domestic silica powder. Spherical silica powder with excellent properties will gradually become the mainstream product and the next important investment outlet in the industry. Yushun New Materials will also plan to complete the Pre-A round of financing in the near future to lay out the production line of spherical silica powder, plan the bottom line of product supply guarantee from a strategic height, and realize the self-sufficiency of spherical silica powder in China as soon as possible.

Copyright 2006-2021, Design placeholder Fulbright Medical Inc.Design by VPA Brand. 沪ICP备17052696号-4